Power Generation

Icon

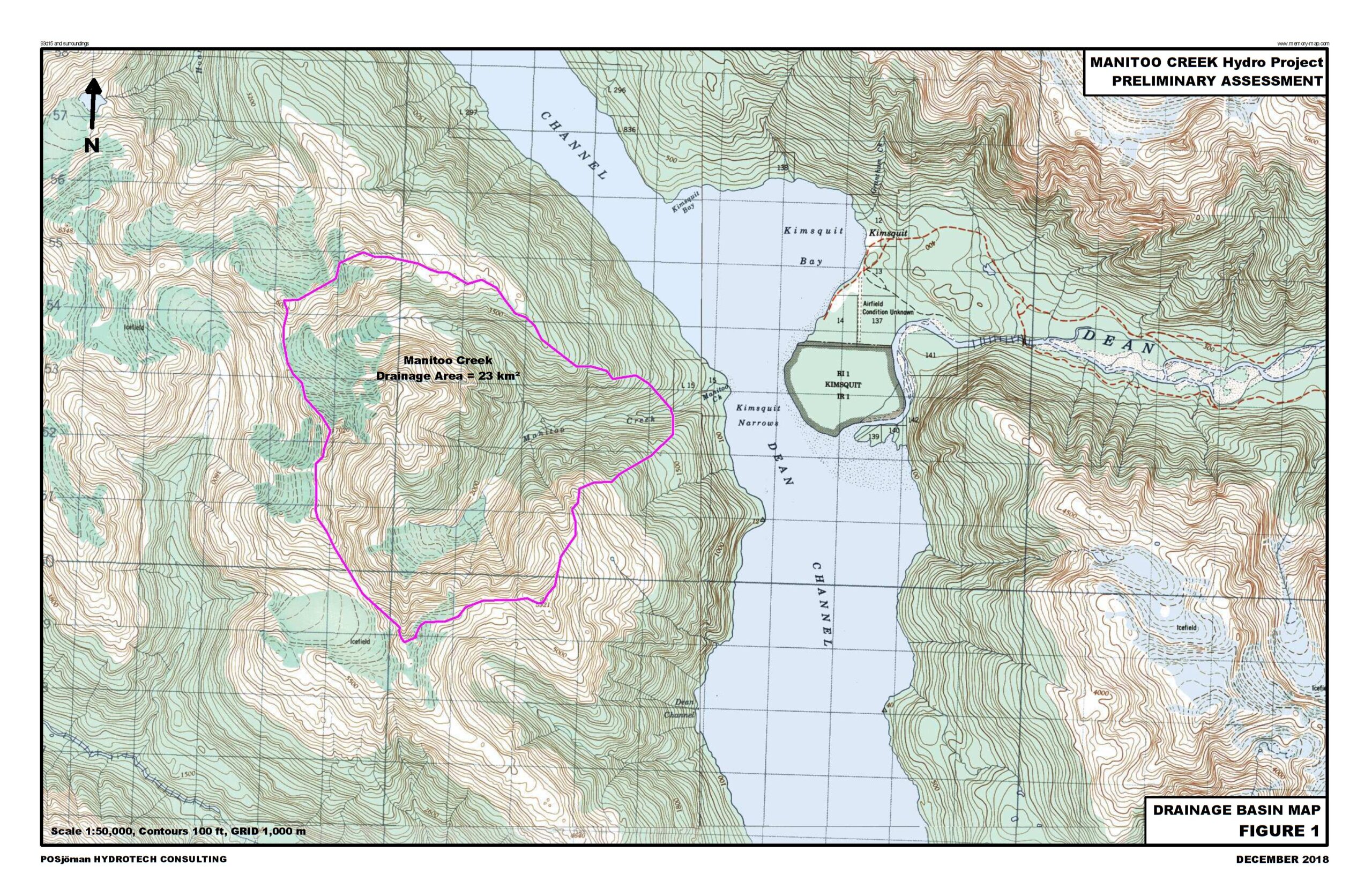

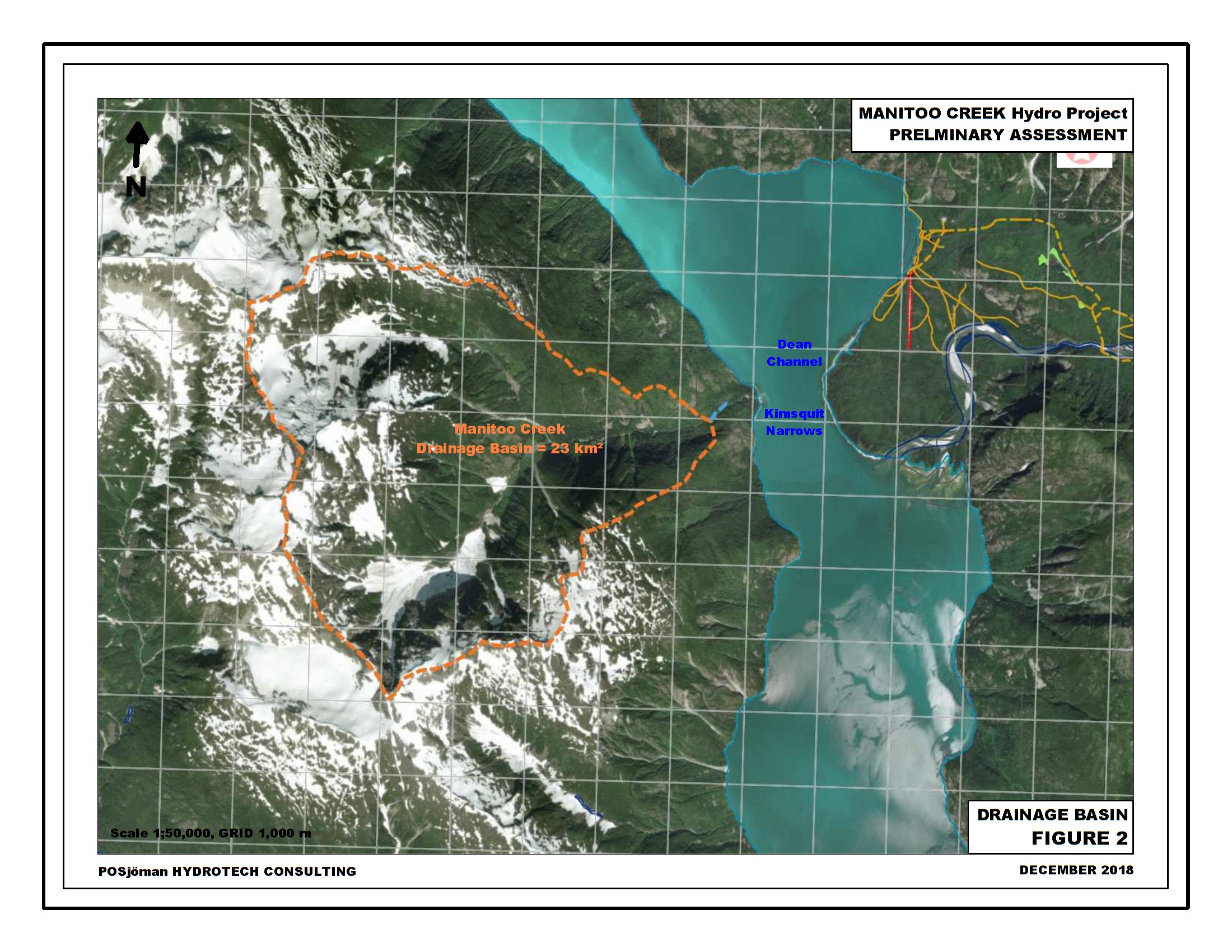

Manitoo Creek Hydro Project - Preliminary Assessment

Icon

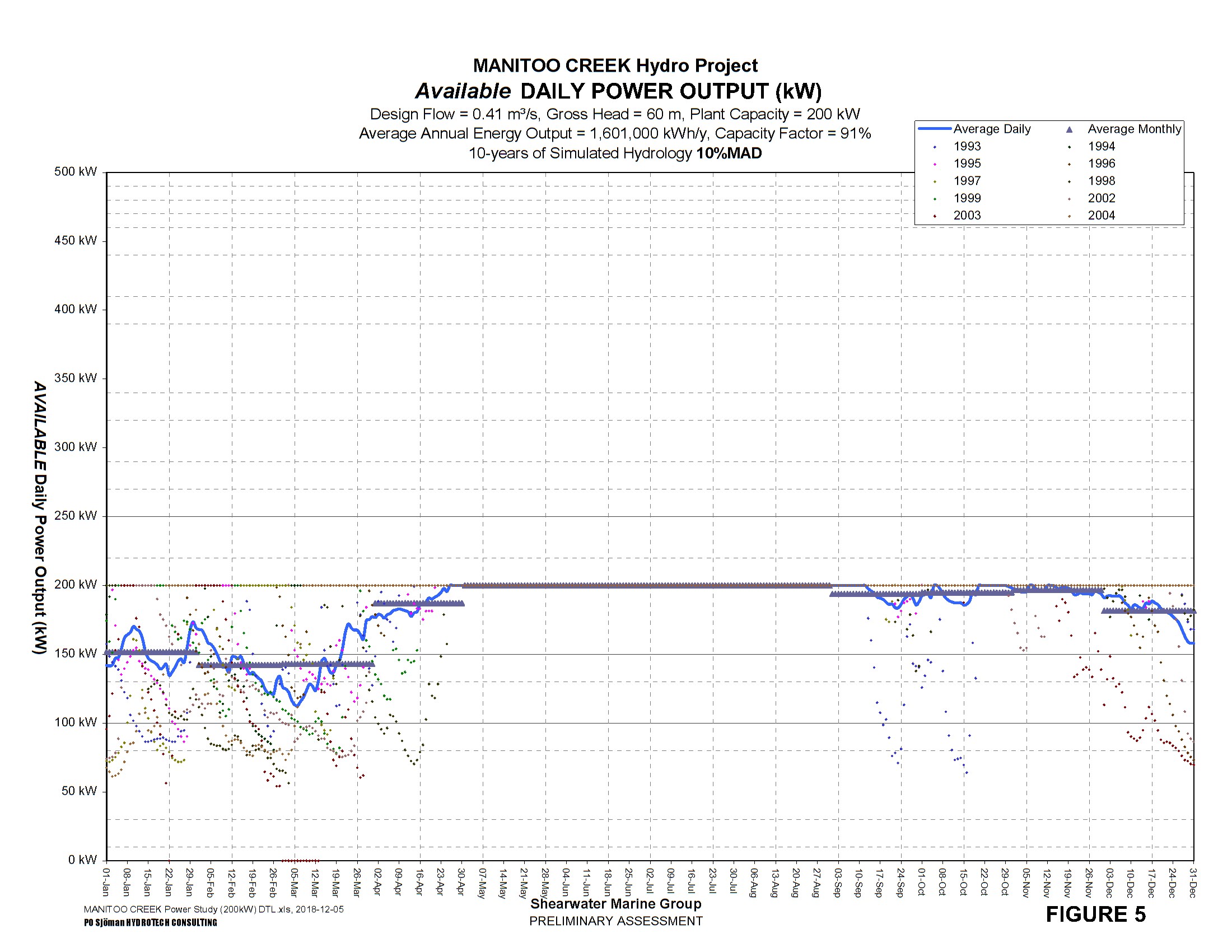

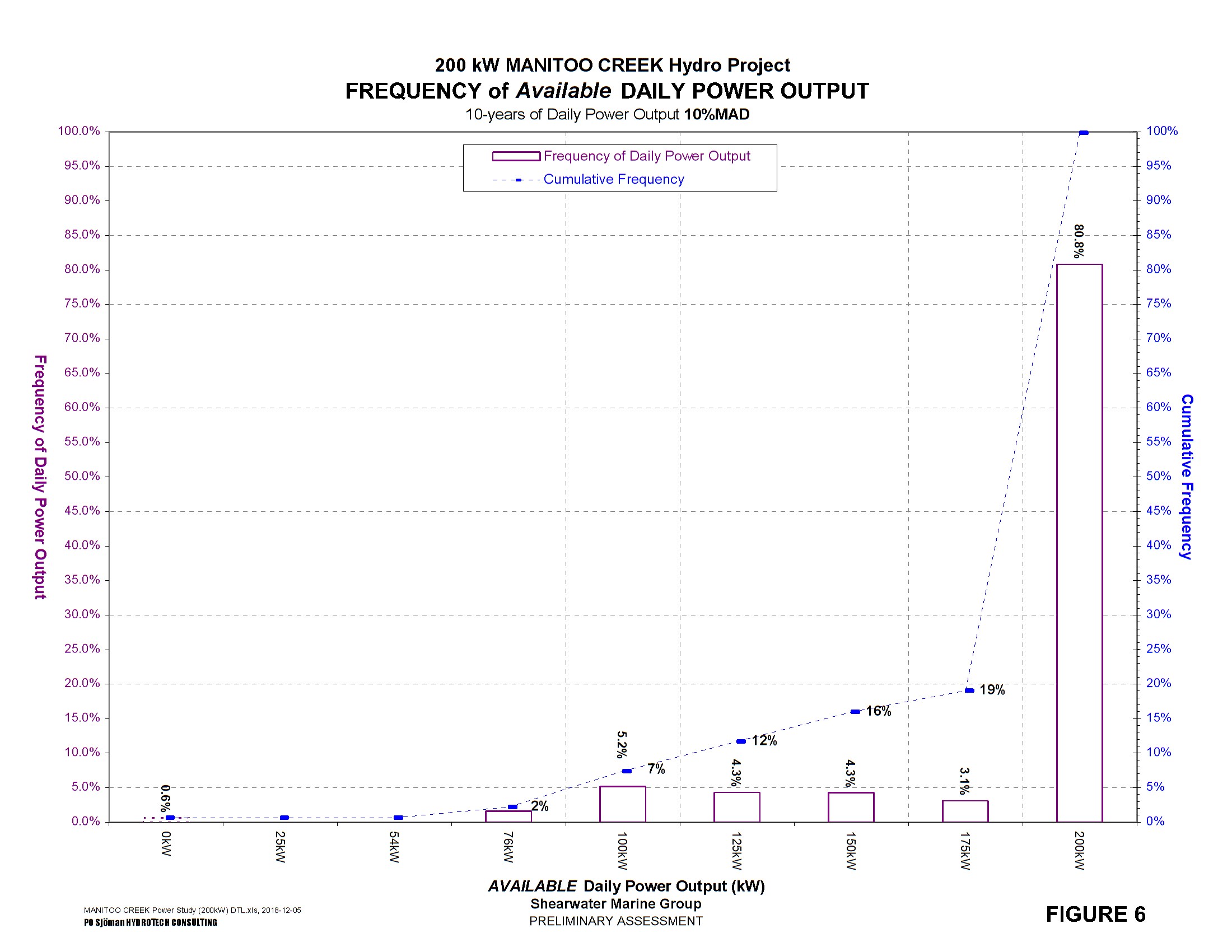

200 kW hydro plant

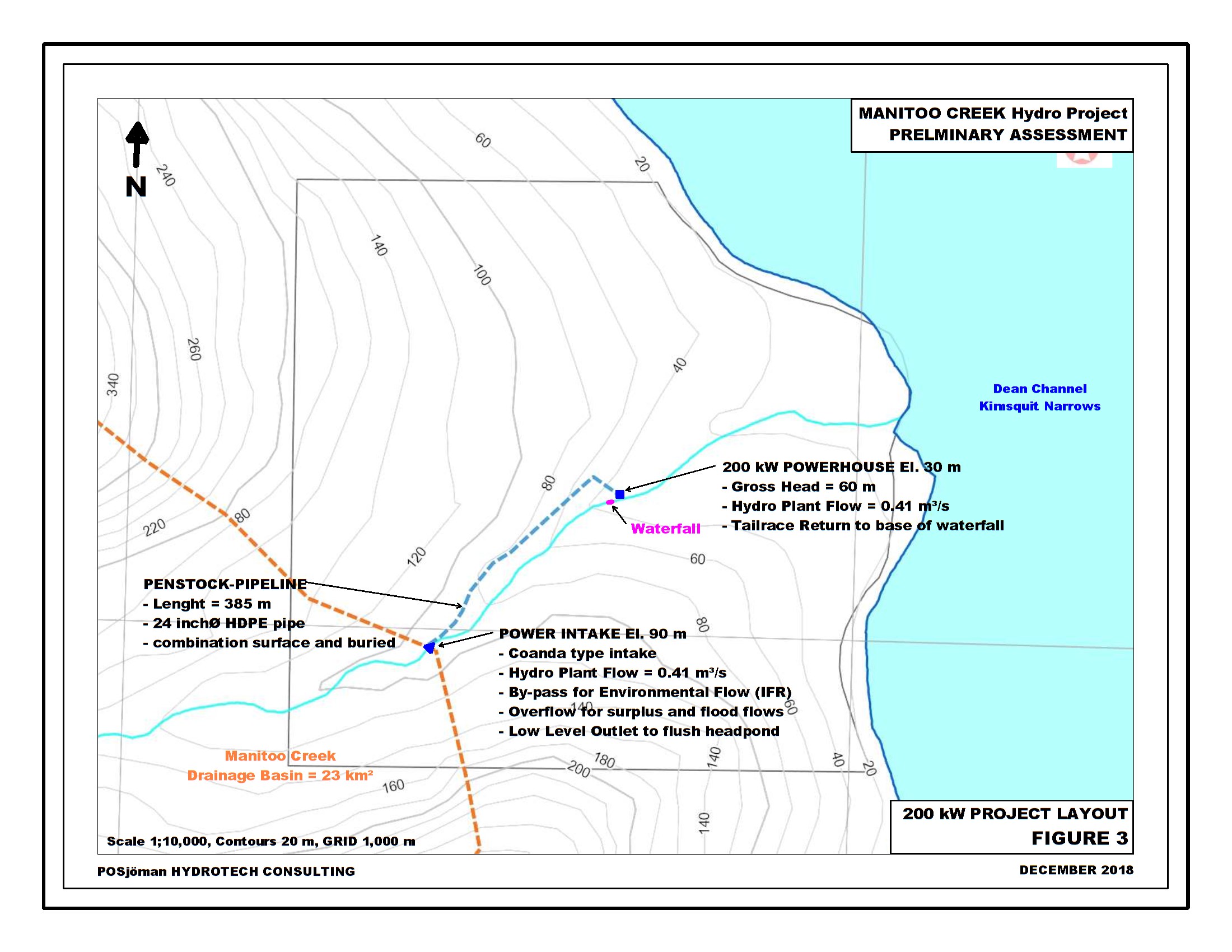

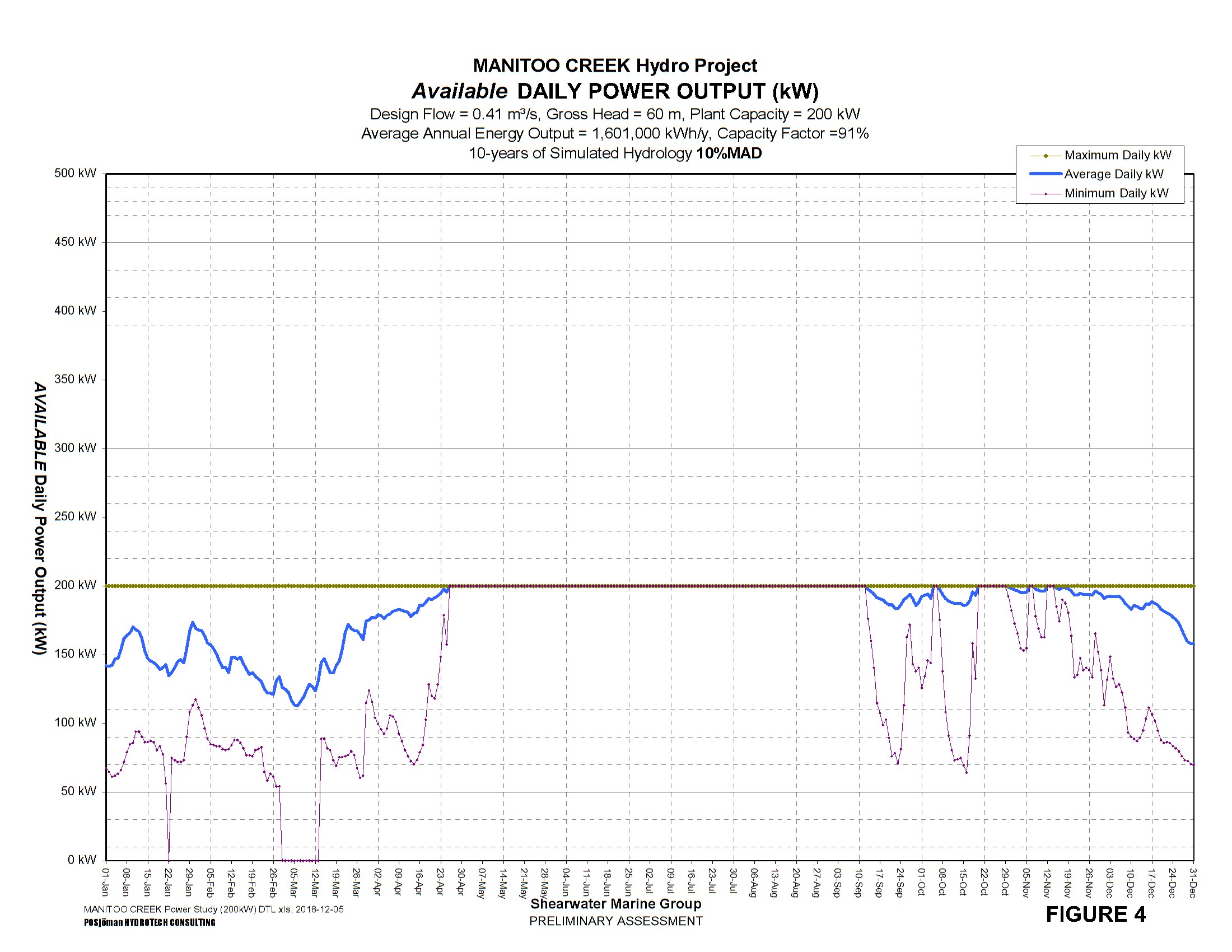

Power Intake at Elevation 90 m 385 m of 24 inchØ HDPE penstock pipe 200 kW powerhouse at Elevation 30 m Gross Head = 60 m (85 psi) Hydro plant flow = 0.41 m³/s (14.4 cfs, 6500 USgpm)

Icon

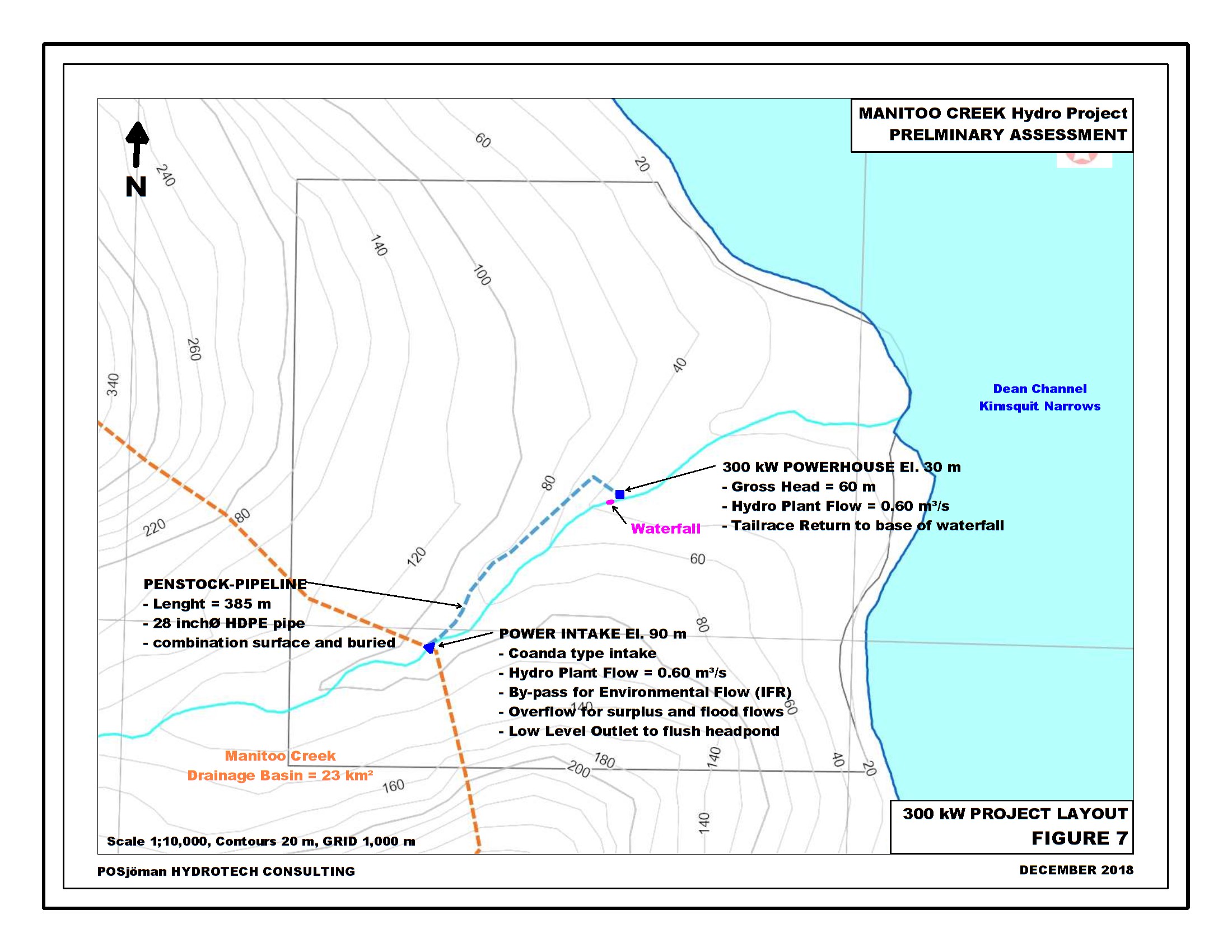

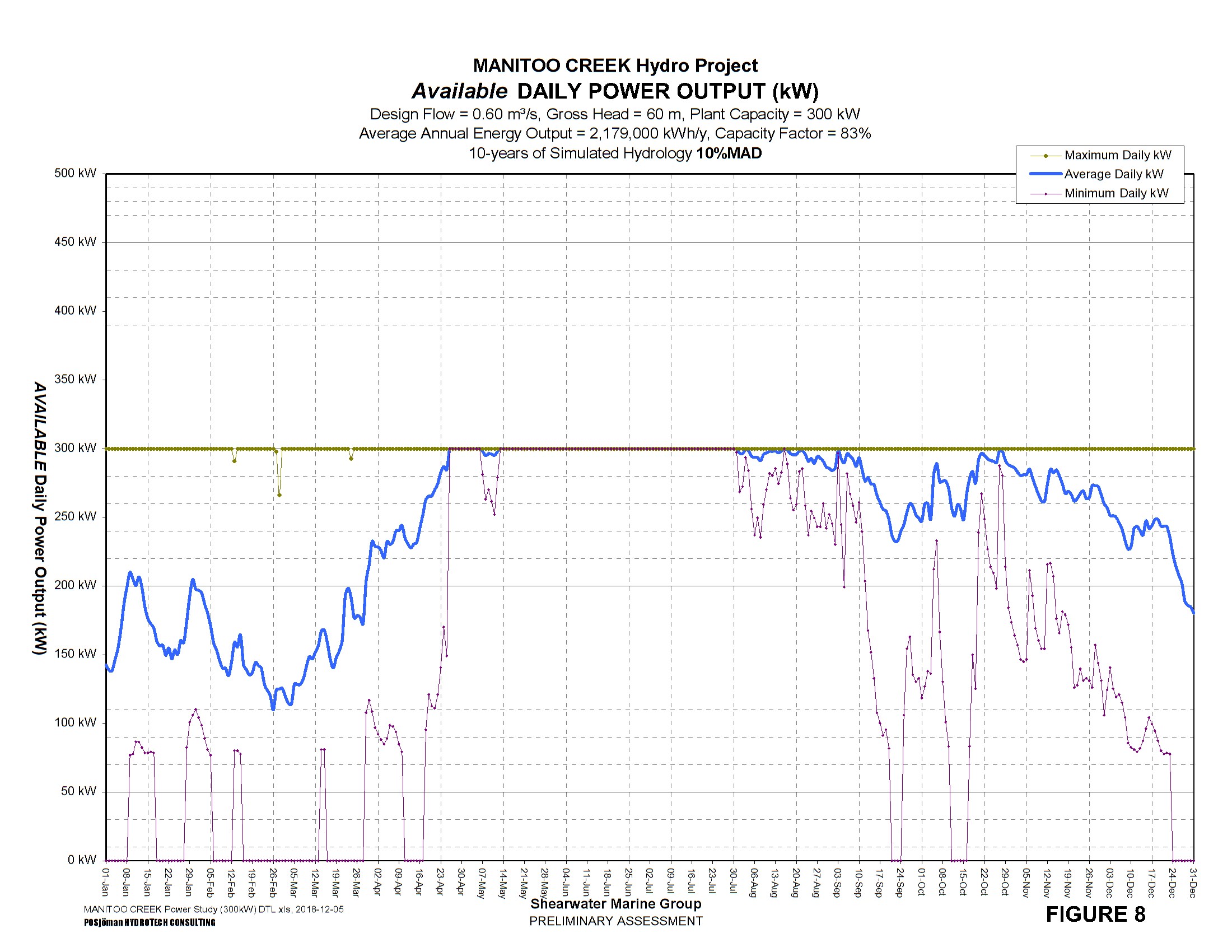

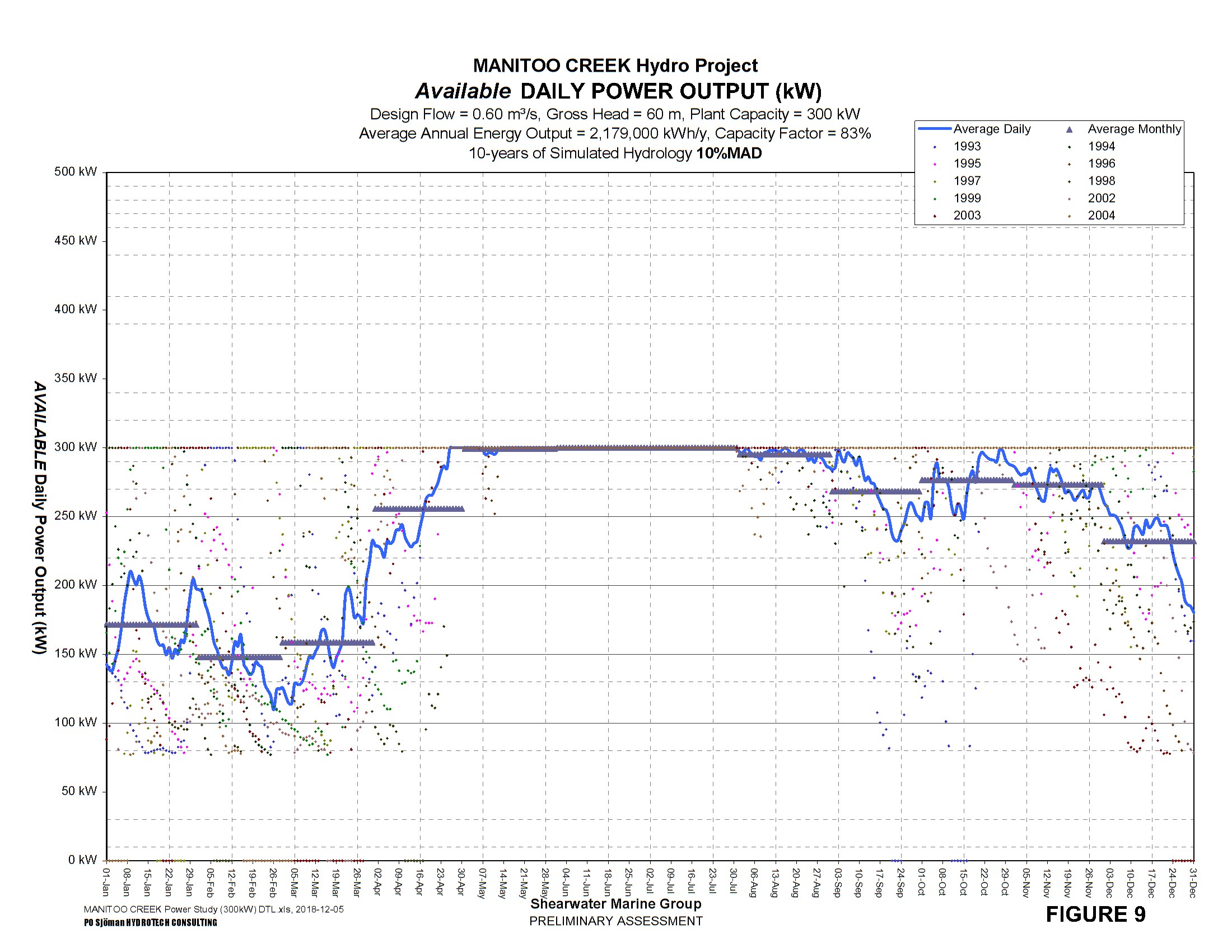

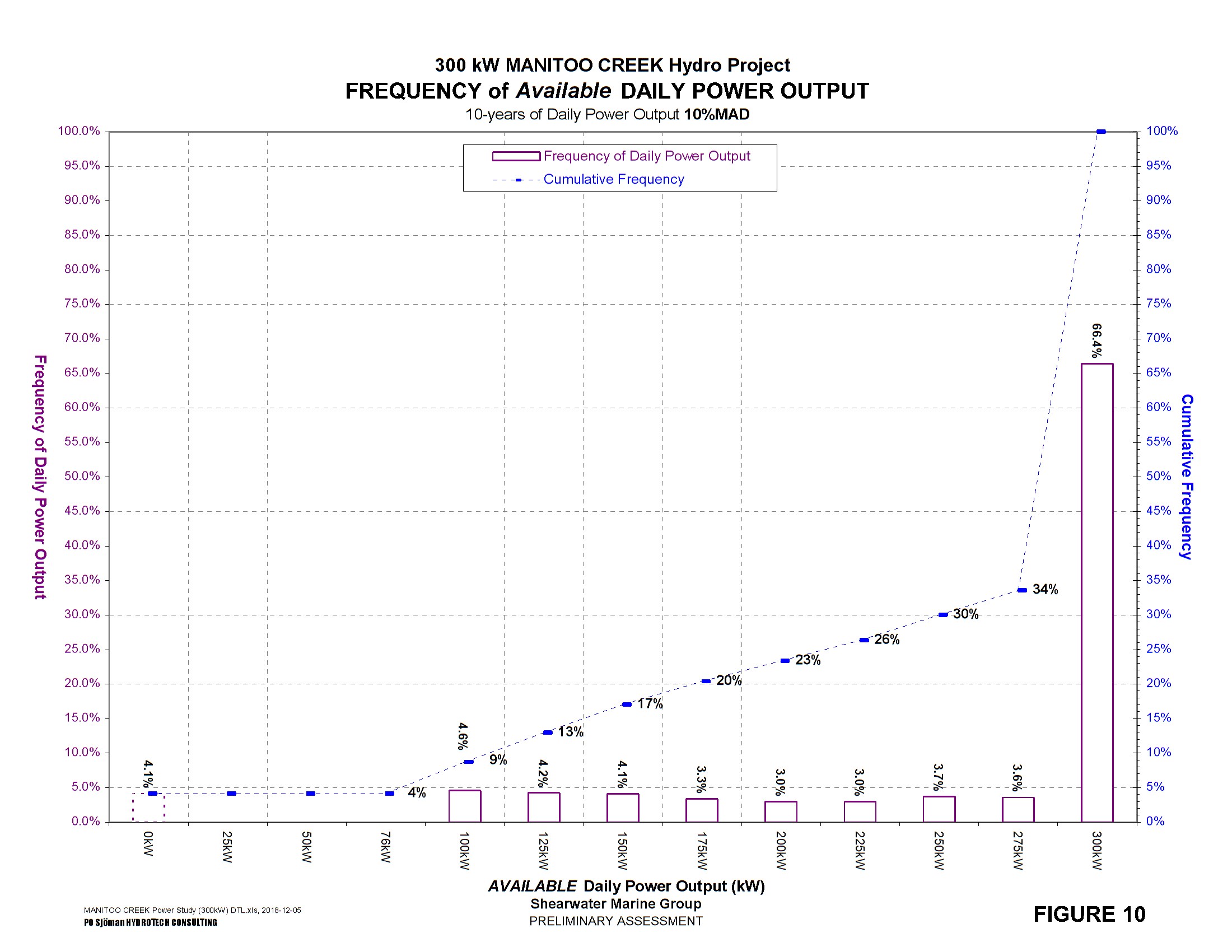

300 kW hydro plant

Power Intake at Elevation 90 m 385 m of 28 inchØ HDPE penstock pipe 200 kW powerhouse at Elevation 30 m Gross Head = 60 m (85 psi) Hydro plant flow = 0.60 m³/s (21.2 cfs, 9500 USgpm)

PROJECTIONS

POWER INTAKE

- We found a bedrock channel at about Elevation 90 m which looks to be a good place to build the intake for the hydro project.

- The intake would consist of a cast-in-place concrete weir across the creek channel with the intake screen on the left side (see attached photo of the intake site).

- The 1 m thick concrete weir would be anchored to bedrock.

- There would be a 1 m x 1 m low level outlet which can be used to flush the smaller sediments from the headpond.

- The power intake would be a COANDA-type intake. The Coanda screen would have 1.0 mm openings to keep the larger sediments from going down the penstock. The stainless steel Coanda screen would include grizzly bars to keep the larger stones off the finer Coanda wedgewires.

PENSTOCK-PIPELINE

- The first 20 to 30 m of the penstock pipe (24inchØ or 28inchØ) would be in the creek channel along a natural rock shelf.

- Most of the penstock-pipeline would be on the intake access road.

- At the downstream the pipe will then go straight downhill to the powerhouse (near the waterfall).

- The penstock pipeline would be High Density Polyethylene (HDPE) pipe, combined surface and buried pipe.

POWERHOUSE

- The powerhouse would be near the base of the waterfall at about Elevation 30 m.

- Barkley on their conceptual layout map indicated that there was a recorded fish barrier about 150 m upstream of the mouth of Manitoo Creek. During the site reconnaissance visit I couldn’t see anything that could be considered a fish barrier other then the waterfall.

- Since the waterfall is a fish barrier the most conservative powerhouse location is near the waterfall so that the flow going through the hydro plant can be returned to Manitoo Creek at the base of the waterfall. Downstream of the tailrace return (waterfall) the hydro plant would not have any impact to Manitoo Creek flows, so no impacts on fish habitat.

- Access to the powerhouse would be along the existing waterfall access road (this access road needs some upgrading).

The 200 kW and 300 kW hydro plant options are illustrated above.

BUDGET (2018)

2018 BUDGET PROJECTIONS

Budget costs for materials only (installation depends on too many unknowns due to remote location)

POWER INTAKE

- Concrete weir, assume 20m³ of concrete @ $2000/m³ = $40,000 (formwork, rebar, mixing and placing)

- Coanda Screen, assume 3 m x 1.5 m Coanda Screen = $5,000

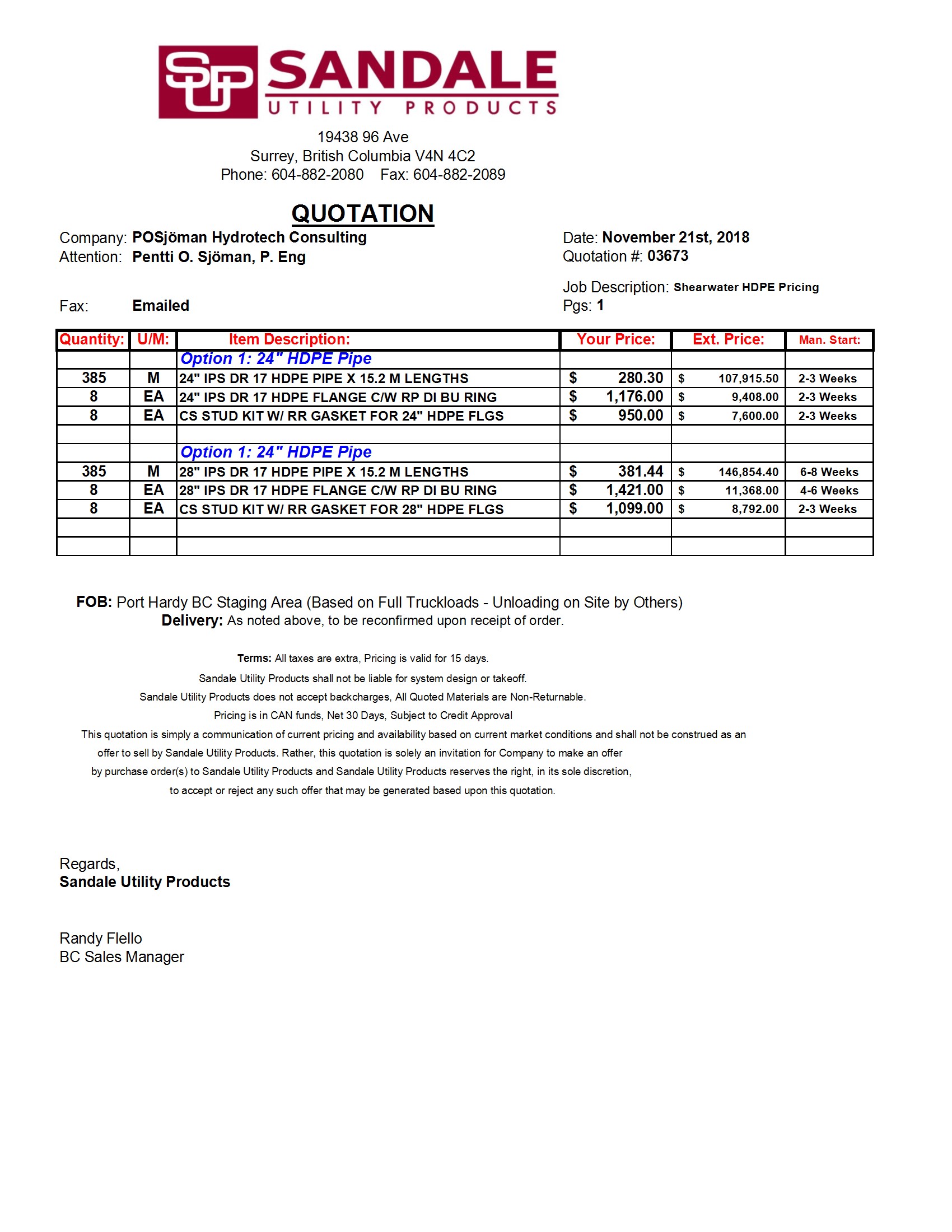

PENSTOCK-PIPELINE

- Penstock Inlet Valve budget $8,000

- HDPE pipe

- 385 m of 24 inchØ = $125,000 FOB Port Hardy

- 385 m of 28 inchØ = $167,000 FOB Port Hardy

- Fusion machine rental and fusion tech to come to site weld pipe

- 2 weeks fusion machine = $18,000 (FOB Surrey, BC)

- 10 day fusion tech = $8,000 (plus travel to site)

- The first 20 to 30 m of the pipe will be anchored to the rock shelf, budget $5,000 for anchor bolts and hardware.

- Access road and pipe installation by others

POWERHOUSE

- Turbine-generator-control cost will be provided by Dependable Turbines

- Powerhouse foundation assume 20m³ of concrete @ $2000/m³ = $40,000 (formwork, rebar, mixing and placing)

- Powerhouse building could be a pre-engineered metal building or a wood framed building (see Dependable Turbines for foot print size).

POWERLINE (Cable)

- Depends on the location of the development at Manitoo Creek.

- Powerhouse is about 500 m inland from Dean Channel

- Powerline by others

ENGINEERING

Detailed civil and electrical engineering budget $150,000.